Most through hole DIP ICs come with their pins splayed out. They have to be bent manually (usually against a table or by hand with pliers). If not bent so that they are straight, the ICs can be very hard to insert, or worse, you can bend one of the pins and break it.

I have broken more pins than I can count. This is why we designed our very own tool to prevent this exact problem.

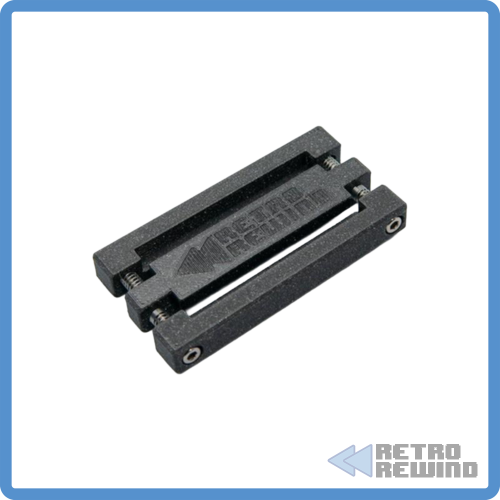

Introducing the DIP CHIP STRAIGHTENER.

With support for both small and large DIP ICs. Simply place your IC in the middle and press firmly from both sides with your hand to straighten your pins. The unit is spring loaded so it will open back up once you are.

Perfectly straight pins that will slide into a socket or PCB with ease have never been easier.

Related Products

27C256 EPROM

27C256 EPROM. Wiped and tested. These are the same stock we use to build our diagnostic cartridges s..

$6.00

27C128 EPROM

27C128 EPROM. Wiped and tested. These are the same stock we use to build our diagnostic cartridges&n..

$5.50

27C512 EPROM

27C512 EPROM. Wiped and tested. These are the same stock we use to build our diagnostic cartridges&n..

$7.00

AmigaOS 3.2

AmigaOS 3.2 comes packed with well over 100 new features, dozens of updates that cover nearly all Am..

$50.00

AmigaOS 3.2.3 Kickstart ROM

Looking for additional physical Kickstart 3.2.3 ROMs for your Amiga? Or do you want to upgrade your ..

$18.00